Laser Cutting

Desert Metal Works fabricates custom industrial, scientific and decorative parts for a wide range of customers. For almost 25 years, Desert Metal Works has been America’s finest laser job shop.

Shipping Worldwide.

What Else We Do

With our CNC Punch and Press Brakes, combined with our Fabrication shop and Powder Painting facility, we can manufacture first class products for almost any industry.

Our Mission

We strive to deliver the highest quality and most competitively priced final product to meet our customer's needs. With our talented staff and cutting edge equipment we are Arizona's most complete laser and fabrication shop.

Providing our customers with the

HIGHEST LEVEL OF SERVICE

SERVICE FIRST

You could say that we have a passion for customer service. No matter the size of your project, we are here to partner with you to create a product that meets all of your needs.

FIND OUT MORE

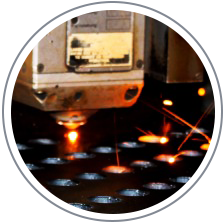

LASER CUTTING

We have mastered laser cutting on a wide range of material types and different thicknesses. We have experience in the widest possible variety of jobs which lets us cut down on set up time and solve problems quickly. Laser cutting is cost effective whether you are cutting through thick or thin.

FIND OUT MORE

CNC PUNCHING

Punching increases our production capabilities dramatically. We can punch mild steel, aluminum, copper, brass and stainless at thicknesses up to 5/16". Owning a Trumpf TC-500R provides Desert Metal Works with many advantages that help make us to deliver the highest quality, most competitively priced product.

FIND OUT MORE

CNC FORMING

Our team of experienced formers can produce high quantities of expertly crafted parts in a short time frame utilizing the accuracy and the consistency of our CNC press brakes. We have Trumpf TruBend and TruUnfold software to program and nest our parts. This lowers our programming time substantially.

FIND OUT MORE

FABRICATION

Our fabrication department works with our dedicated staff to ensure attention is paid to every detail. We know that an on time delivery is critical to your success and we all share a commitment to make that possible. A can-do attitude permeates our organization and that always helps our customers.

FIND OUT MORE

POWDER PAINTING

Desert Metal Works has a state of the art powder painting facility for putting the finishing touches on every part we produce. Our powder paint staff has decades of experience. They have painted a wide variety of parts and weldments with most types and manufacturers of powder paint.

FIND OUT MORE

Expanding business since June of 1990.

BIG FACILITY, BIG CAPABILITY

First in Southern Arizona to offer CNC laser cutting to our customers.Utilizing CNC punching and CNC forming along with our lasers to increase our maximum output.Talented team of employees who are committed to serving our customers’ needs. Able to conform to our customers’ specifications and requirements. Guaranteed to offer the most competitive pricing and to strive to meet all delivery dates.